Mirror Silver Coating, Stainless steel, Aluminium, Titanium press working.

High precision mechanical parts

Ever since foundation of our company in 1943, we have contributed to development of Japanese industries, gaining high trust and appreciations from our customers.

Our high precision press working techniques originates from manufacturing of shutter wings for single lens reflex cameras.

Our burr-less shutter wings made of hardened steel received high appreciation from multinational camera makers.

Even though trend has shifted from film camera to digital camera,

it is still true that to achieve high speed continuous shoot of 8 shots per seconds and high mechanical durability, integrated techniques of advanced precision stamping, heat treatment, and antiwear surface treatment are essential.

In addition to mechanical parts related to a shutter of camera, Iwata’s high precision stamping has produced a lot of core parts for such key devices as auto focus device, mirror box, and etc.

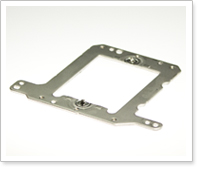

Mirror box part

Mirror box part

Frame of a mirror box

Fixture of a single lens reflex

camera's accesories

Fixture of a sensor dust unit

Lens fixture

Manufacturing of high grade steel covers

Both rigidity and thinness are needed for digital camera covers and mobile phone covers.

IWATA has provided high grade and high quality stainless steel covers to major camera and mobile phone makers.

IWATA's Cover

- IWATA has high reputation and accumulated know-how for stable and reliable massproduction of stainless steel covers, which are used for high-end digital cameras.

- Integrated manufacturing : Mold design and development, surface coating and treatment.

- HIgh craftmanship is required for drawing operation of staineless steel. IWATA performs drawing of very thin stainless steel with remarkable accuracy.

IWATA has manufactured stainless steel covers since the time of film cameras.

We now manufacturs stainless steel covers for digital cameras.

With abundant experiences in stainless steel cover massproduction, we provide high grade and high quality stainless steel covers through integrated production of mold design and development, high precision stamping, surface coating, and surface treatment.

Our achievement

- Compact digital camera IXI/Power shot series ...Canon

- Compact digital camera Cybershot series ...Sony

- Compact digital camera LUMIX series ...Panasonic

- Compact digital camera EXILIM series ...CASIO

- Compact digital camera COOLPIX series ...NIKON

Features of IWATA's camera

IWATA's metal stamping and surface coating techniques produce slim mobile phone covers with higher rigidity and stylish appearance.

- Metallic tone

Metallic tone of stainless steel, titanium, and aluminium increases appearance quality. - HIgh rigidity

High rigidity stainless steel body enable a mobile phone to be thinner and more stylish.

Our achievement

- Titanium mobile phone covers by TOSHIBA

Light weight and high rigidity mobile phone covers made through drawing operation and hemming all the edge. - We manufacture products with our high grade surface coating and surface treatment to major Japanese mobile phone makers.

- Disc Spring,

Retaining Ring - Disc Spring

- Retaining Ring

- Surface Coating,

Mirror Silver Coating - Surface Coating

- Mirror Silver Coating